Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimise workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Zebra's public sector technology solutions enhance decision-making, streamline operations, and safeguard communities with advanced software and rugged hardware.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Adapt to market shifts, enhance worker productivity and secure long-term growth with AMRs. Deploy, redeploy and optimize autonomous mobile robots with ease.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customise your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Zebra's location technologies provide real-time tracking for your organisation to better manage and optimise your critical assets and create more efficient workflows.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

The everything you need to rapidly and cost effectively develop high-performance AI vision applications on Zebra mobile computers.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labour costs low, your talent happy and your organisation compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximising IT resources and minimising down time.

Make the most of every stage of your scanning journey from deployment to optimisation. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

Boost warehouse and manufacturing operations with Symmetry, an AMR software for fleet management of Autonomous Mobile Robots and streamlined automation workflows.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customisation starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximise productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

What Is Plastic Card Printing?

What Are Plastic Cards?

Plastic cards are prevalent in our daily lives, from credit cards to driver’s licenses, and membership cards to employee identification badges. Their standard size, portability and durability make them the ideal choice for many applications.

Digital plastic card printers offer the ability to create customized cards on demand, right at the point of issuance. With a computer and an image capture system, such as a digital camera, plastic card printers provide the delivery point of a highly integrated system. At just a few seconds per card, the printing process is fast, so that cards are generated and personalized immediately, quickly connecting the customer or cardholder to the issuing organization or program.

Digitally printed plastic cards provide numerous technological features, but start with a blank card that can be printed with any combination of artwork, graphics, text, digital photograph, bar codes, logos, etc., limited only by the issuers’ imagination.

Additional machine-readable information, such as magnetic stripes and smart card chips, can also be encoded.

How to Print on Plastic Cards

All Zebra plastic card printers feature the same basic printing operations; dye sublimation and/or thermal transfer printing. Both techniques involve heating a thermal print head while in contact with a ribbon. However, thermal transfer printing differs from dye sublimation in that thermal transfer uses ink rather than dye. In thermal transfer printing, heat melts the ink on the ribbon, causing it to transfer to the card surface. In dye sublimation, heat vaporizes the ribbon dye, which then permeates the plastic card.

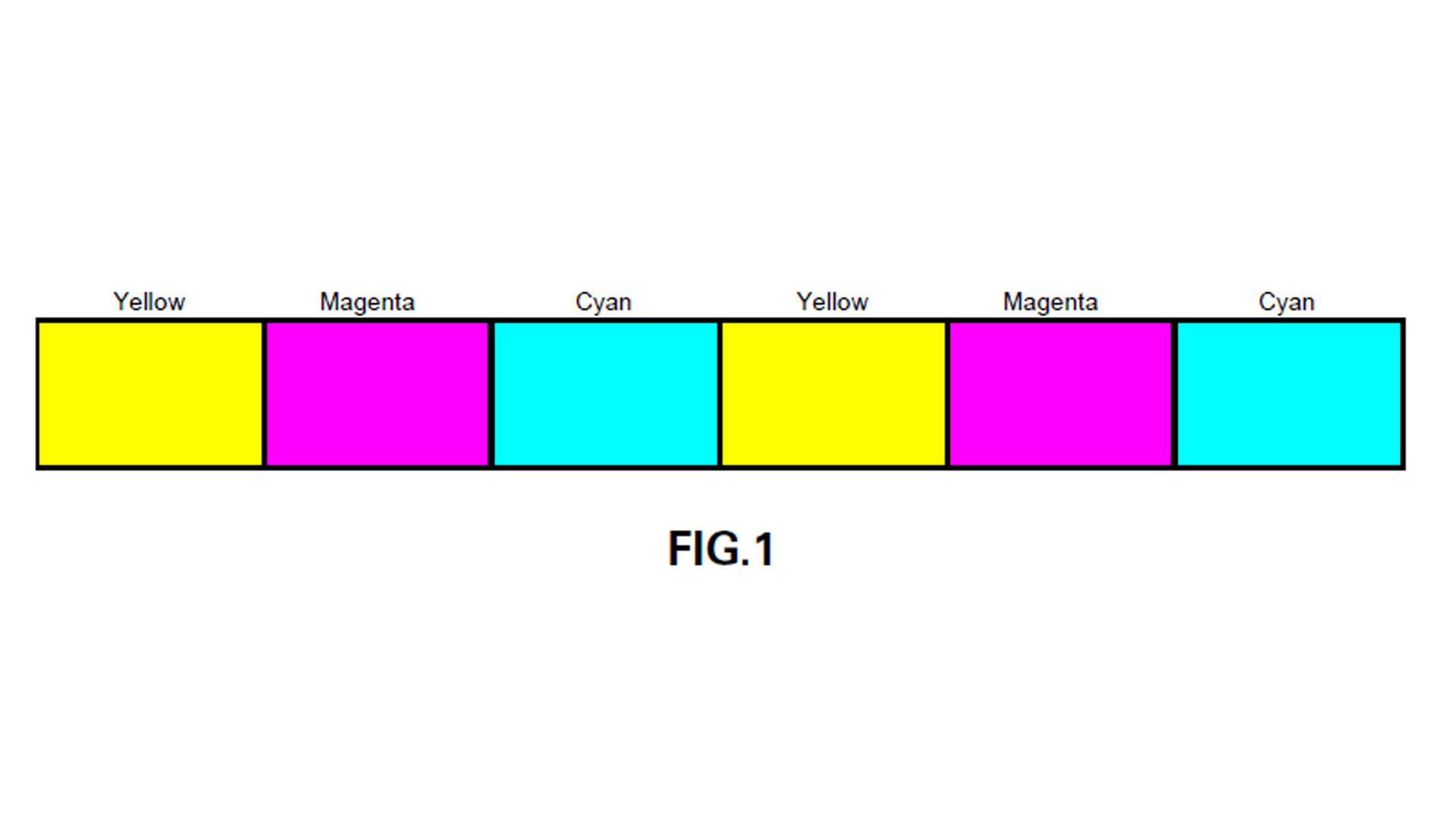

The ribbon used in colour dye sublimation printing is divided into three separate colour panels Yellow, Magenta, and Cyan (see Figure 1). This configuration is referred to as YMC.

These three colours are the primary colours used in printing to produce all other colours including black. The dye from the ribbon is applied to the plastic card via a multi-pass operation. This means the card will pass under the print head once for each of the three coloured ribbon panels - applying each colour separately.

‘Dye Sublimation’ is also referred to as Dye Diffusion. When the print head heats the dye on a ribbon, the dye is transformed from a solid to a gas and diffused onto the plastic card, which is specially coated to absorb the colour dye. The temperature of the print head controls how much dye is converted to a gas – as the print head temperature rises, more dye can be absorbed into the plastic card.

Consequently, the picture quality and continuous colour tones produced by a dye sublimation printer – at 300 dpi – can outperform most laser or ink jet printers with higher resolutions. The advantage of dye sublimation is the millions of colours that can be created. Varying the heat intensity on the ribbon panels yields various shades of each colour, making colour selection virtually unlimited.

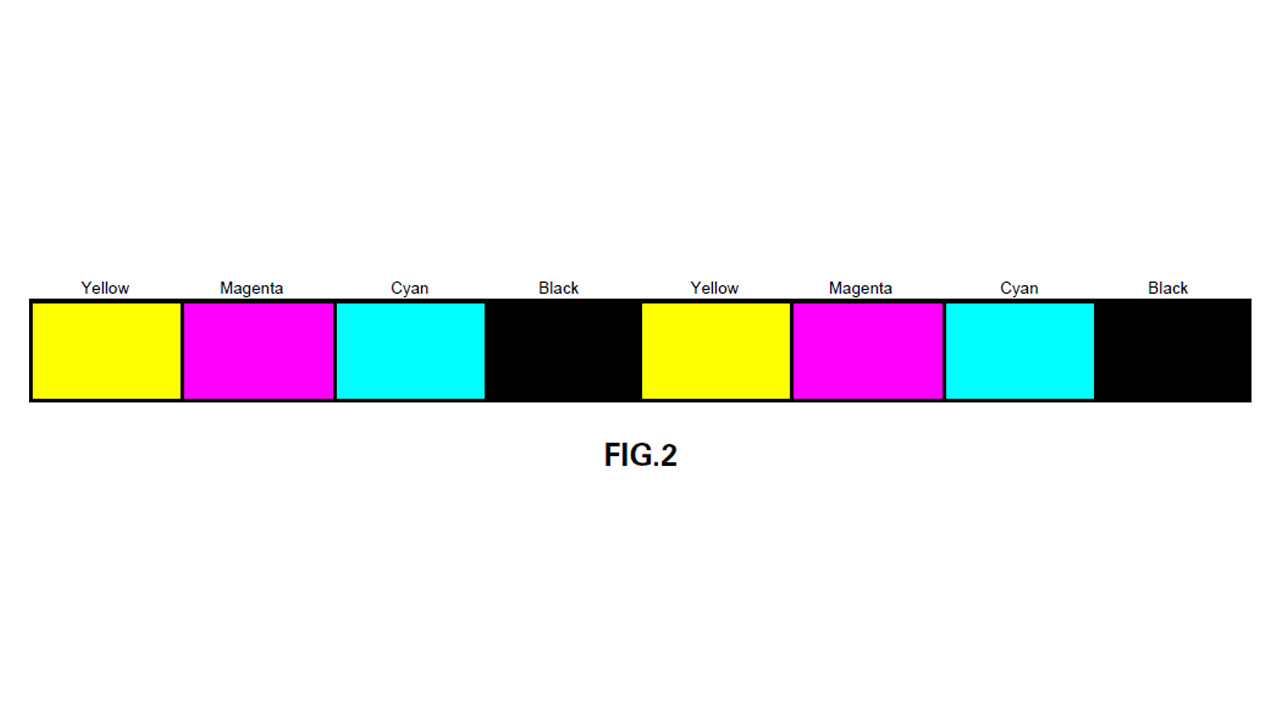

As mentioned above, thermal transfer differs from dye sublimation in that it uses ink instead of dye. However, both dye sublimation and thermal ink (sometimes referred to as Resin) can be combined in one ribbon (see Figure 2). This ribbon is known as a YMCK Ribbon. The letter “K” designates the colour black in the printing industry .

Why Do You Need a Separate Black Panel, When You Can Create Black by Mixing the Three Basic Ymc Colours Together?

The black created by mixing the YMC colours together is referred to as “Composite Black.” Composite Black is not recommended for printing bar codes since it does not produce the sharp edge many scanners require. Although this is invisible to the naked eye, it is easily observable under magnification). Composite Black is also invisible to IR scanners since there is no carbon in the dye. Since you may not know what type of scanner will be used, the rule is to always use TT (resin) black to print bar codes.

All Zebra printers are capable of printing in monochrome using a single colour ribbon. These ribbons are less expensive than full colour multi-panel ribbons and can be either dye or ink (thermal transfer). The most commonly used monochrome ribbon is “Black” but there are several other colours available including; Red, Green, and Blue.

Dye Sublimation ribbons are preferred for printing pictures, since they can produce many shades of gray for a smoother look and a better picture quality. A resin black picture normally uses a dithered gray scale (gray made from a combination of pixels which limits the number of shades), producing a coarser, grainy look to the image.

Thermal Transfer (resin) or monochrome ribbons should be used to print text, bar codes or single colour graphics such as simple logos. The letter “K” followed by a lower case “r” or “d” (Kr or Kd) denotes black monochrome ribbons. The “r” designates a Thermal Transfer ribbon with resin ink.

The “d” designates a dye sublimation ribbon. Monochrome ribbon colours include black, red, green, blue, white, metallic silver, metallic gold, and scratch-off gray.

What Is a Magnetic Stripe Card?

Magnetic stripe cards have been in existence since the early 70’s when they were used on paper and film-based ID cards as well as credit cards. Magnetic stripe technology is widely used throughout the world and remains the dominant technology in the United States for transaction processing and access control.

Other technologies such as PDF bar codes and smart chip cards are now capturing part of the magnetic stripe market since they can hold more information.

Magnetic Stripe Encoding Terms

Coercivity

A technical term used to designate how strong a magnetic field must be to affect data encoded on a magnetic stripe. Coercivity is measured in Oersteds (Oe). Coercivity is the measure of how difficult it is to encode information in a magnetic stripe.

HiCo

Abbreviation for High Coercivity. HiCo magnetic stripes provide the highest level of immunity to damage by stray magnetic fields. They are more difficult to encode than LoCo magnetic stripes because the encoding requires more power. HiCo magnetic stripe cards are slightly more expensive for this reason.

LoCo

Abbreviation for Low Coercivity. Easier to encode and slightly less expensive than HiCo magnetic stripe cards.

Selecting which type of magnetic stripe to adopt depends on how the card is to be used. Will the magnetic stripe be used daily, once a month, or just a couple of times a year? The chart below shows some of the applications where magnetic stripes are used and which stripe is common for that application.

Typical Magnetic Stripe Card Applications , Types and Usage

| APPLICATIONS | LOCO | HICO | USAGE |

| Access Control | Daily | ||

| Retail Customer Loyalty Points | Weekly | ||

| Membership Cards | Weekly / Monthly | ||

| Time and Attendance | Daily | ||

| Debit/Credit | International | United States | Weekly / Monthly |

| Drivers Licence | Occassional* |

* HiCo required by most states

The easiest way to determine visually if a stripe on a card is HiCo or LoCo is by the colour. HiCo stripes are black and LoCo stripes are a lighter brown. Magnetic stripe readers are “blind” as to whether a stripe is HiCo or LoCo and are designed to read both.

Another term often used is Stripe-up and Stripe-down. Stripe-up means the magnetic stripe is on the front of the card and Stripe-down means the magnetic stripe is on the back of the card. This information is important when ordering a printer since the magnetic encoder must be installed differently for Stripe-up and Stripe-down models at the factory. The most common is Stripe-down.

All Zebra Encoders follow the ISO standard for encoding, but can be changed via the Windows driver to enable proprietary encoding. Proprietary encoding offers greater security and most readers can also be easily reprogrammed to read custom encoding.

What Are Smart Cards?

There are a wide variety of contact and contactless smart cards currently in use.

The terms “Smart Chip Card, IC Card, and Smart Card” all refer to the same type of card. Smart cards feature an embedded, programmable chip and can store over 100 times more information than a magnetic stripe. They can also be reprogrammed to add, delete or rearrange data.

Invented in Europe in the 1970s, smart cards were in wide use by the early 1980s. Smart cards are an easy, inexpensive way for European businesses to do off-line transaction verification. Off-line verification is preferred throughout Europe due to the high cost of telecommunications. In contrast, the cost of having the current magnetic stripe readers “on-line” via telecommunications is relatively inexpensive in the U.S. compared to the rest of the world. Thus, the United States has been slow to implement smart cards because it would require replacing the widely installed magnetic stripe card reading equipment with smart card readers.

The second type of smart card contains both a microprocessor as well as memory.

Not only can these cards can store massive amounts of information, but the micro-processor enables the card to make independent decisions regarding the information stored.

Zebra card printers can accommodate both types of chips, since they all offer an optional smart card contact station or embedded encoder. The printer brings the card into the contact station and then passes programming signals from a programmer to encode the smart chip.

Contactless smart cards utilize various RFID technologies to write and read. Many card printers print on these kinds of smart cards. Encoding or programming the electronic devices on these cards is typically accomplished by an external encoding or programming device, but contactless smart card encoders integrated into the card printer available.

What are Proximity Cards?

Proximity cards are primarily used for access control applications. They are similar to contactless smart cards, but are passive, read only devices. Proximity cards contain embedded RFID antenna and can nominally be read from distances up to 10”. They can also be programmed uniquely, and utilized in many applications other than access control such as time and attendance, employee certification, emergency medical data storage, and biometric verification.

Card Durability and Security

Various types of materials are used to protect plastic cards from abrasion, wear, fading, alternation, and duplications. Overlay varnishes and laminates are the most common materials used to enhance card durability and provide additional security.

Card durability has to do with how well the card withstands various forms of environmental stress. They include resistance to abrasion, such as passing the card through a magnetic stripe or bar code reader, protection from image fading when exposed to sunlight, and resistance to damage when immersed in water or exposed to chemicals.

Another important factor in applications such as drivers licensing is resistance to tampering, alteration, and/or replication. With the use of protective materials such as laminates with holograms, cards can be constructed to eliminate the potential of tampering and alteration.

Card security means that the card can be verified for authenticity. Techniques include the application of overlay varnish or laminate materials with hologram images. Use of these materials in constructing cards makes replication by anyone without access to the custom hologram image materials virtually impossible.

Card Protection Materials

| MATERIAL | CARD LIFE | DURABILITY | SECURITY |

| Overlay Varnish | Up to 2 years | Minimal | |

| Overlay Varnish with Hologram | Up to 2 years | Minimal | Visual |

| Clear Laminate | 5 to 7 years | High | |

| Laminate with Hologram | 5 to 7 years | High | Visual |

Overlay varnishes provide card protection, but have a much shorter life span than laminate material - and offer very little security (with the exception of some hologram varnishes). Varnishes are not a solid covering and have multiple tiny holes in the surface, which allows the dyes to be drawn away from the card. This will cause the image on the card to blur and fade due to UV light, shift in colour, or just wear away. The life expectancy of a plain plastic card is up to 2 years.

Laminate material offer better protection than plain varnish, for both security and life expectancy. Laminate material is a polyester protective material that is applied to the surface of the card after printing. Laminates are available either 0.6 or 1.0 mil thick and are applied via a hot roll laminating station. The life expectancy of a plastic card with a laminate material is up to seven years.

Digital Card Printing Advantages

Image Quality

The image quality of digitally printed plastic cards produced with is far superior to those produced through the traditional method described above. Not only are digitized photo images sharper, but also they can be edited for color quality. Moreover, positioning of graphical elements on the card is more consistent, and text is both clearer and more readable.

Flexibility

Plastic card printers can print text, line art, and photographic images. They can also encode magnetic stripes and provide smart card chip programming contact stations, all in a single step process. Card design software provides users the flexibility to change designs, store and access multiple designs, create variable text fields, and implement database programs to store images and track information.

Security

Plastic card printers can also apply various protective materials, such as hologram overlays and laminates, to make cards resistant to tampering and alteration. This helps make cards more secure because they cannot be easily reproduced or counterfeited. These protective materials also help to increase card life.

Durability

Card protection materials such as overlay varnishes and laminates provide various levels of card durability by making the cards resistant to abrasion, UV light exposure, water damage, and exposure to liquid chemicals.

Economy

In-house printing of plastic cards using a Zebra card printer is far more cost and time-efficient than the traditional photographic cut/paste/laminate method. A plastic card printer is also more economical than using a lithographic printer or service bureau. Outside suppliers must mark up card production costs significantly in order to cover overhead and servicing costs, making them cost-effective only for large volume applications.

Convenience

Printing your own plastic cards gives you the convenience of being able to produce cards on demand, when and where you need them. Having your own card printer capability also makes it easy to make changes to card content or design quickly.

Explore Zebra's Range of Card Printing Solutions

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2025 Zebra Technologies Corp. and/or its affiliates.