Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimise workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Zebra's public sector technology solutions enhance decision-making, streamline operations, and safeguard communities with advanced software and rugged hardware.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Adapt to market shifts, enhance worker productivity and secure long-term growth with AMRs. Deploy, redeploy and optimize autonomous mobile robots with ease.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customise your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Zebra's location technologies provide real-time tracking for your organisation to better manage and optimise your critical assets and create more efficient workflows.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

The everything you need to rapidly and cost effectively develop high-performance AI vision applications on Zebra mobile computers.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labour costs low, your talent happy and your organisation compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximising IT resources and minimising down time.

Make the most of every stage of your scanning journey from deployment to optimisation. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

Boost warehouse and manufacturing operations with Symmetry, an AMR software for fleet management of Autonomous Mobile Robots and streamlined automation workflows.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customisation starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximise productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

Bosch Further Automates Inspection Process With Enhanced Vision System

Bosch needed a machine vision solution to further automate its mark-reading and verification process. It also wanted to enhance the traceability of the injector nozzles, thus reducing the number of machined parts requiring post-production manual inspection.

Zebra Success Story: Bosch Group

Overview: Automotive Challenge

Bosch wanted to improve its process quality and traceability of products by further automating the inspection process. A goal of the new vision system was to reduce the number of machined parts requiring post-production manual inspection.

Benefits / Outcomes

- Reject rates have decreased to 5% for a production volume of 7,000 parts per day

- More effective reading of laser engraving directly on the metal parts, as well as verification that the shot-peening operation has been successfully completed

- Integration of a flexible, robust software capable of working with a range of GigE Vision® and USB Vision® camera models

- A support network in Brazil and Canada, with access to on-demand online training

About Bosch Group

Leading global supplier of technology and services, the Bosch Group has been a major player for more than a century. With divisions worldwide, its operations are focused on four distinct business sectors: mobility solutions, industrial technology, consumer goods and energy and building technology. At the Bosch outpost in Curitiba, Brazil, the company’s primary focus is on developing solutions for the diesel engine injection systems for the automotive industry. Its customer base consists of multinational companies working with diesel, as well as off-road and commercial vehicles companies.

The Challenge

“When it comes to the manufacturing of Bosch’s diesel injector nozzles, the process involves the operator selecting the specific parts to be produced, then feeding those components into the machine for production; once completed, the operator withdraws the inspected and packaged parts. These injector nozzles are a critical engine component, working to move diesel fuel into the engine’s combustion chamber for vehicle propulsion. The team at Bosch uses vision technology for traceability and verification purposes, as the design and quality of these components is of utmost importance.

“At the request of the production line team, Bosch sought out an enhanced vision system, wanting to improve the mark-reading and verification process, as well as the traceability of the injector nozzles. The aim was to reduce the number of machined parts requiring post-production manual inspection. “We had the opportunity to further automate the inspection process,” says Moises Santana, vision system designer with Bosch, “The new system can handle three independent processes simultaneously using the same computer.”

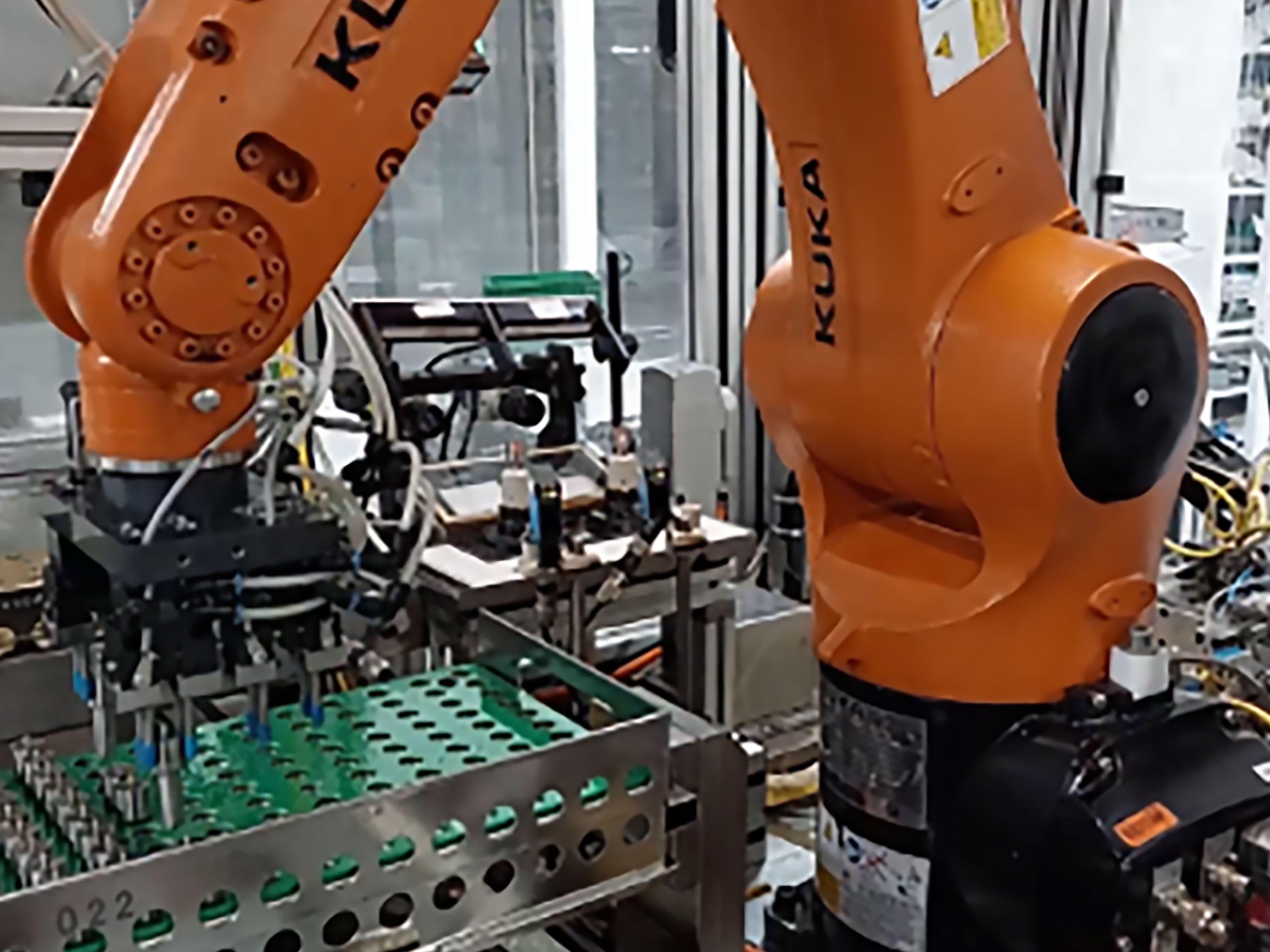

The newly updated vision system comprises a quad-input Zebra Concord PoE frame grabber and a Zebra Indio I/O card inside an industrial PC with an Intel® i7 core running Aurora Design Assistant software, which controls the whole system. Three front light bars from LumiVision ensure adequate illumination. An industrial KUKA robot correctly positions the metal components so they can be photographed by the three GigE Vision cameras from Teledyne Dalsa; after the image capture, the robot repositions the injector nozzles further down the line.

“There are so many good reasons that led us to acquire the new vision system,” notes Santana. “The software tools are remarkably agile. It is a flexible vision system capable of working with several models of GigE Vision and USB Vision cameras.”

There are so many good reasons that led us to acquire the new vision system. The software tools are remarkably agile. It is a flexible vision system capable of working with several models of GigE Vision and USB Vision cameras.

Moises Santana, Vision System Designer, Bosch

The Solution

The three GigE cameras form an integral part of the vision system: two perform optical character recognition (OCR) and optical character verification (OCV) of a code on the nozzles themselves, while the third reads the barcode label affixed to the outside of the packaging tube that encloses the final product. Bosch needed the precision of machine vision technology to read the human-readable codes engraved on the cylindrical metal surface after the shot-peening process.

A clever element of Bosch’s system is how it uses an area scan camera—rather than a line scan version—to scan the cylindrical injectors. This process involved collecting a series of images of each nozzle as it rotates, and then stitching the center stripe of each image together to create an unwrapped, flattened picture.

Once unwrapped, the numerical codes in each image can then be read using the StringReader step in Aurora Design Assistant software. This approach allowed the Bosch team to reduce its setup time, simplify its installation and reduce costs. “We used a combination of software steps for this project, including CircleFinder to locate shapes and StringReader for character recognition,” Santana says, “as well as a number of image filters and customized tools to send and receive images to external applications.”

“The graphical interface in Aurora Design Assistant is friendly to use,” Santana continues, “as well as the online training through its on-demand platform. We also received great technical support from Sensor do Brasil. All in all, the Bosch team felt supported the whole way through.”

Using the flexible Aurora Design Assistant software, the team at Bosch was able to effectively pack three inspection and verification processes into a single vision system, which significantly decreased the overall system cost.

The Zebra Difference: Outcome and Benefits

A Silver Bullet Solution

Building the vision system took about one month, a tremendous feat for a system of this complexity. The system itself is simple to operate; a single machinist, with no prior machine-vision expertise, can easily manage the operation.

The Brazilian Bosch office was pleased with the self-directed learning through the Vision Academy training platform; its team also requested application-development support, specifically with regards to creating a montage of the flattened images using Aurora Design Assistant and to configure communication with the programmable logic controller (PLC). Santana smiles, noting that “the response time from the support team was appropriate and competent.”

Conclusion

With the new vision system online, Bosch is already looking to add an additional two cameras to the process, to inspect defects on the surface of the injector nozzle and replicate the solution to a second machine. “We anticipate developing future projects using a similar vision system,” Santana says, “We see additional applications using artificial intelligence (AI), incorporating smart cameras as well.”

The Brazilian Bosch team found Aurora Design Assistant to provide both the flexibility and ease-of-use it hoped for, especially with the range of branded and third-party hardware that makes up the system. Santana affirms, “The level of technical support available locally in Brazil, plus the accessibility of online training was incredibly advantageous. From acquisition to analysis and processing of images, everything was smooth, and had the possibility of real-time visualization, really making this a solution that satisfies the exceptional quality standards of Bosch’s products.”

Using the new vision system, the Curitiba plant achieves production volumes of 7,000 parts per day and has decreased the daily percentage of false rejects to 5%, a significant improvement over previous iterations.

Featured Products and Solutions

Related Resources

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2025 Zebra Technologies Corp. and/or its affiliates.