Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimize workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Learn how Zebra's public sector technology solutions empower state and local governments to improve efficiency with asset tracking and data capture devices.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

Zebra's range of Banking technology solutions enables banks to minimize costs and to increase revenue throughout their branch network. Learn more.

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's location technologies provide real-time tracking for your organization to better manage and optimize your critical assets and create more efficient workflows.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Adapt to market shifts, enhance worker productivity and secure long-term growth with AMRs. Deploy, redeploy and optimize autonomous mobile robots with ease.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customize your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

The everything you need to rapidly and cost effectively develop high-performance AI vision applications on Zebra mobile computers.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labor costs low, your talent happy and your organization compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximizing IT resources and minimizing down time.

Make the most of every stage of your scanning journey from deployment to optimization. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

Boost warehouse and manufacturing operations with Symmetry, an AMR software for fleet management of Autonomous Mobile Robots and streamlined automation workflows.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customization starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximize productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

The Zebra Knowledge Center provides learning expertise that can be tailored to meet the specific needs of your environment.

Zebra has a wide variety of courses to train you and your staff, ranging from scheduled sessions to remote offerings as well as custom tailored to your specific needs.

Build your reputation with Zebra's certification offerings. Zebra offers a variety of options that can help you progress your career path forward.

Build your reputation with Zebra's certification offerings. Zebra offers a variety of options that can help you progress your career path forward.

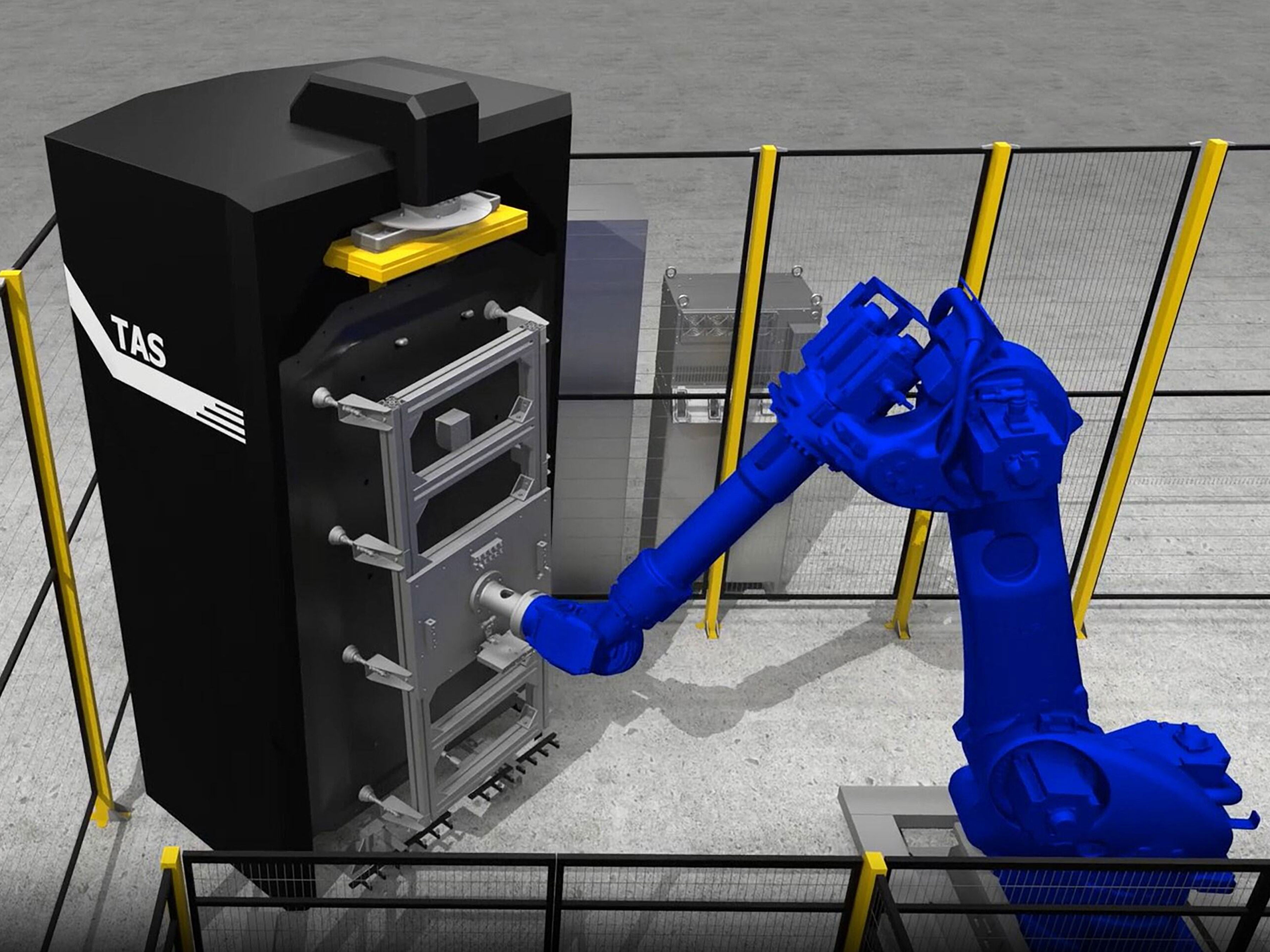

TAS GmbH Enhances Quality Control of EV Battery Tray Covers with Zebra Aurora Vision Studio™

TAS GmbH turned to Zebra’s Aurora Vision Studio™ with deep learning to ensure high-quality finishing of EV battery compartment covers. A robotic system with custom-built cameras inspects each component for defects, improving detection over time.

Zebra Success Story: TAS GmbH Oberflächentechnik

Overview: Manufacturing Challenge

TAS GmbH must ensure the high-quality finishing of metal surfaces, particularly battery compartment covers for electric vehicles, to meet stringent automotive industry standards. This requires precise detection of defects such as coating irregularities, surface scratches and laser marking issues, demanding a robust and reliable inspection system.

Benefits / Outcomes

- Increased and consistent product quality

- A machine learning system that improves as it is used

- Increased reliability, precision and safety

Customer

TAS GmbH Oberflächentechnik

Kreuzwertheim, Germany

Partner

Industry

Manufacturing

Solutions

About TAS GmbH Oberflächentechnik

TAS GmbH specializes in surface technologies. Thanks to its precise finishing of metal surfaces, the company plays a decisive role in the manufacture of automotive components - especially in the covers for battery compartments in electric vehicles, in which the high-voltage batteries are installed. They protect the high-voltage batteries from external influences such as moisture, as they could otherwise burst into flames due to corrosion. The battery compartments must therefore be precisely sealed with the covers.

TAS GmbH comprehensively inspects every part for defects and improves its system’s ability to recognise them using camera technology and sophisticated image processing software. This is a testament to the skilled engineering team behind the image processing solution, which is based on the Aurora Vision Studio with its Deep Learning add-on - a machine vision integrated development environment from Zebra.

The Challenge

TAS GmbH relies on a meticulous process to ensure a precise finish for every component and to meet the high demands of the automotive industry. A robot arm handles the covers for the battery compartments and feeds each one to an inspection device. Here, a camera system checks the covers for possible defects such as irregularities in the coating, scratches in the surface or problems with the laser marking that could affect the quality. The cameras are conceptually arranged in such a way that they can capture the covers in their entirety. The camera system was customised for TAS GmbH by ID Engineering, a Zebra Registered Reseller and Industrial Automation System Integrator.

The special feature of this image processing solution is the deep learning technology of Zebra Aurora Vision Studio. It can be trained to recognise and classify certain types of defects using images. To do this, previously selected image data sets are annotated and fed to the system. The system can then be retrained to recognise new inspection criteria based on the information or fine-tuned for defects already known to the system. As a result, the image processing solution can be constantly developed and improved using deep learning technology.

"With Zebra’s machine vision system, we have shown we can meet the high-quality standards of the automotive industry. Zebra’s solutions have fully met our expectations, and we are already planning to implement this technology in future projects," says Temel Tas, Managing Director at TAS GmbH.

With Zebra’s machine vision system, we have shown we can meet the high-quality standards of the automotive industry. Zebra’s solutions have fully met our expectations, and we are already planning to implement this technology in future projects.

Temel Tas, Managing Director at TAS GmbH

The Solution

A core benefit to the system’s deep learning capability is that the inspection process remains flexible even when the industrial conditions change. This is a significant advantage over image processing solutions with traditional tools, which may not be as durable or adapt well to changing production conditions.

The need for precision and reliability in detecting even the smallest surface defects that could compromise the reliable sealing of electric vehicle battery compartments with the corresponding covers was the deciding factor for the customised camera system and image processing solution. Thanks to the adaptability of Aurora Vision Studio with the Deep Learning add-on, these safety measures continue to gain in precision and efficiency.

The Zebra Difference: Outcome and Benefits

The flowchart-based image processing solution with deep learning technology used by TAS GmbH follows a no-code approach. This enables convenient and fast training of the image processing solution while maintaining consistent quality, which underlines TAS GmbH’s commitment to quality and puts the requirements of the automotive industry first.

"The main advantages of Zebra’s Aurora Vision Studio are its speed in development and in execution. The scalable Zebra system is easy to use and it’s no code solution meant a fast development. In addition, the execution time when analysing many and sometimes large image files simultaneously is much faster than with other technologies that we have tested. Beyond the technology, we appreciate the valuable support from Zebra and their fast reaction times," says Michael Sartor, Head of Machine Vision Department at ID Engineering.

"The solution from ID Engineering and TAS GmbH is a good example of how learning algorithms can be used and ensure better quality in industrial production. With Aurora Vision Studio and the deep learning add-on, we are providing a basis on which even huge amounts of data can be processed and utilised. This is our contribution to the manufacturing technology of the future," says Rudolf Schambeck, Senior Manager Machine Vision Solutions DACH at Zebra Technologies.

Through the combination of advanced surface technology, a customised quality control system and deep learning technology, TAS GmbH represents a significant advance in quality control in the automotive industry. Zebra’s machine learning technologies enable the company to demonstrate its strong and continuous commitment to innovation and quality in the industry.

Related Resources

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2025 Zebra Technologies Corp. and/or its affiliates.